How does it operate

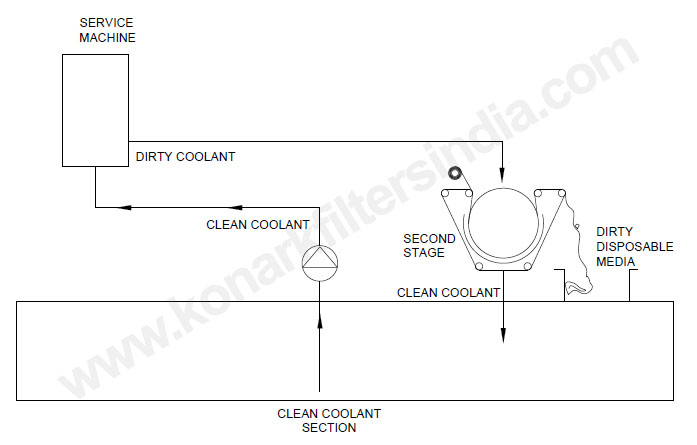

KoGraMax is a unique gravity drum filter. Suspended particles and tramp oil is effectively separated in this filter. Dirt laden disposable filter media is discharged out automatically at a pre-determined cake build up inside the drum.

Advantages

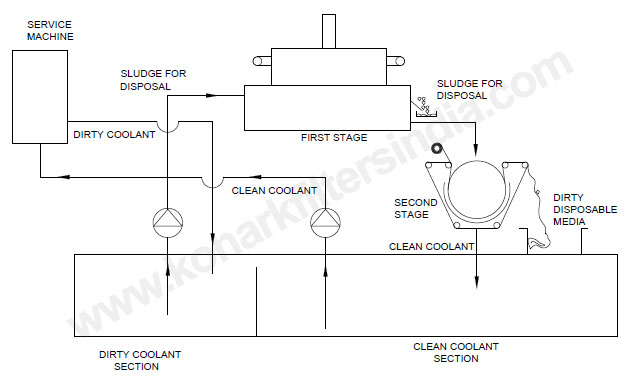

For emulsion coolant, neat cutting oils, synthetic oils and many more. Konark Filters unique Two stage coolant filtration system. KoMagFlo is a combination of our 2 finest filters.

Applications - honing, grinding, ball lapping, fine metal cutting, metal pre-treatment line There are 3 main contaminants ingress into the cutting fluids..

How does it operate

KoMagFlo is made up of two sections. First one is KONSEP.. a high gauss value strong magnetic positive filter. This removes maximum ferrous metal dirt load and oil. Second in series is our KOGDRUM. This is a gravity drum filter. The unseparated non-ferrous parts and remaining tramp oil is removed in this section. Dirty coolant from service machine enters dirty coolant tank. It is pumped from here into the first section. Dirt is trapped on the surface of media. At a pre-determined time the media is cleaned and dirt discharged into the bins automatically. The first section cleaned coolant enters second section by gravity. The fully cleaned coolant is let in clean coolant tank by gravity from where it is pumped back to the service machine. The dirty disposable paper media alongwith the dirt is discharged out in the collection bin automatically.

Advantages

Credentials of KoMagFlo