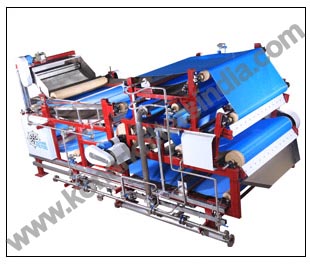

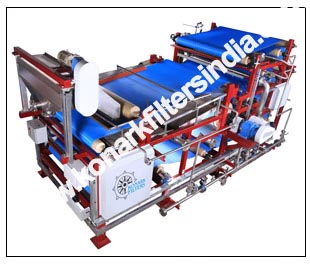

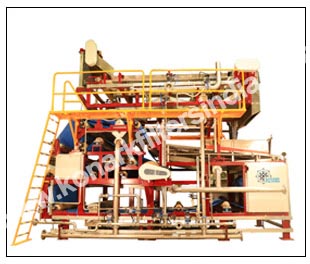

We are Manufacturer, Supplier and Exporter of Belt Press Filters / Filtration Systems (Kobelt SQ Twin) for ETP (Effluent Treatment Plants) and STP (Sewage Treatment Plants) Sludge Dewatering application. Our Manufacturing unit is situated at Pune, Maharashtra, India.

Advantages

- More than 95% volume reduction is quick time.

- Highlydewatered sludge output.

- Compact.

- Least operator intervention.

- Climate independent performance.

- Unique multi-section design eliminates cloth clogging.

- Intelligent hydraulic loading and mass balance.

- Least operation and maintenance costs.

- Helps meet EHS. pollution and ISO 14000 norms.

Description

- Sludge management takes almost 1/4th of ETP operating cost.

- Conventional drying beds, filter presses, decanters etc. can not meet the needs.

- Belt press filter is the answer.

- KONARK FILTERS' KOBELT-SQ-TWIN is the best answer.

Operation

Sludge is dewatered by applying mechanical pressure on conditioned sludge between two tensioned filter belts passing through decreasing diameter serpentine configuration.